We’ve taken a complex process and simplified it so that you can quickly understand the arc flash study, why you need it and what the outcomes will be for your new build or existing facility project.

An arc flash study is conducted by a professional electrical engineer to evaluate arc flash hazards of an electrical distribution system and to educate workers on hazards associated with their workplace. Basically, an arc flash study evaluates the electrical safety of a workplace facility and highlights the risks and potential hazards present in electrical systems.

What should you expect at the end of the arc flash study?

We often hear things like:

- “What is an arc flash label?”

- “How do I get an arc flash sticker?”

- “What are the PPE recommendations for my site?”

- “Why do I need an arc flash study?”

- “What does an arc flash study tell me?”

Arc flash studies are complex studies that result in two simple deliverables – an arc flash label (sometimes called an arc flash sticker) and a comprehensive report.

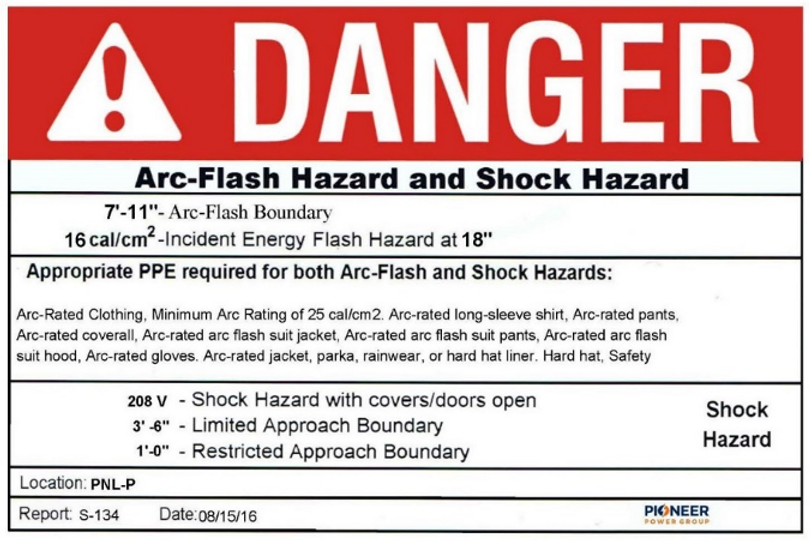

Arc flash labels are designed to warn workers of hazards and to provide recommendations on required Personal Protective Equipment (PPE) when in the area. Each area of concern in a facility will receive a label. The information on each label is directly dependent on the results of the arc flash study.

Of course – there is much more to the study – it’s not just about an arc flash label, even if that’s what many people think of as the final deliverable. Our comprehensive power studies include accurate arc flash equipment labeling, fault current analysis, protective device coordination evaluation, PPE recommendations and suggestions to improve system safety and protection.

Arc Flash Study outcomes include:

- Arc flash labels detailing critical arc flash & shock hazard information

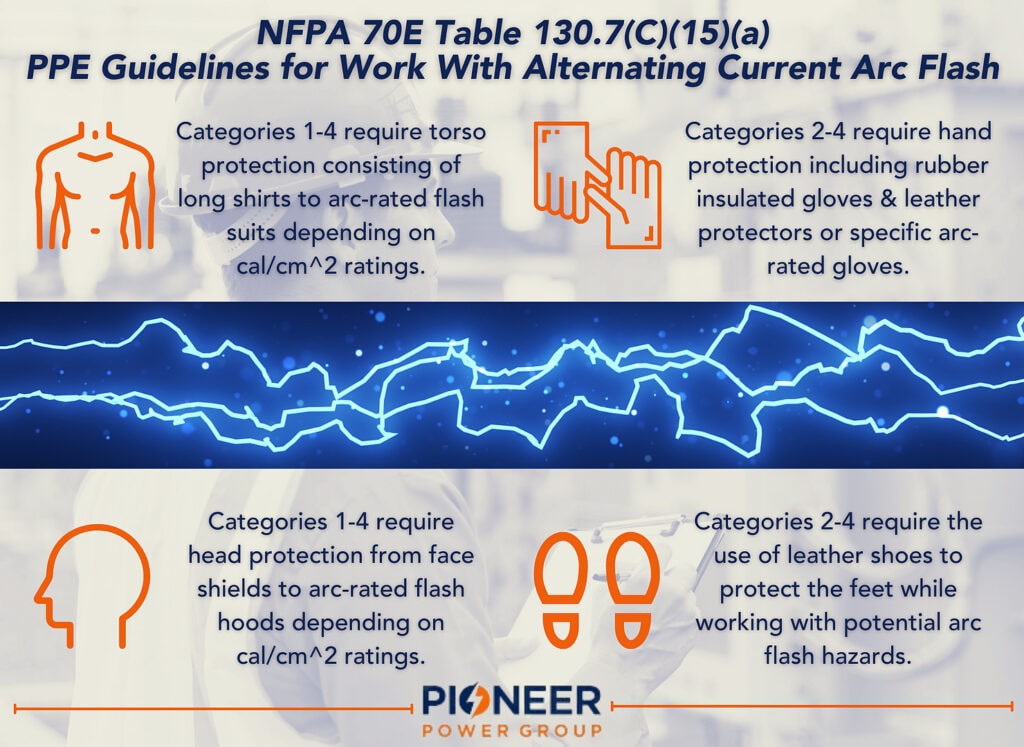

- PPE recommendations to ensure personnel safety

- A short circuit study: to ensure all equipment is adequately rated for the installation

- A protective device coordination study: to ensure that there are no code issues, to certify that all electrical equipment is adequately protected & to optimize overcurrent settings thereby minimizing the likelihood of large power outages

- Identification of potential hazards to improve system safety & protection

Arc Flash Studies for New Build & Existing Construction Projects

All new construction projects should plan on conducting an arc flash study prior to initial start-up.

When planned properly, there should be plenty of time to complete the study before the system is energized. Activating new equipment before arc flash labels have been installed could be very risky. Employee safety and PPE requirements should not be considered in hindsight. By incorporating an arc flash study at the beginning of your project you are ensuring that the project proceeds smoothly without any undesired shutdowns, costly equipment failures or personnel injuries.

Our engineers have performed thousands of arc flash studies. We pride ourselves on a quick quoting process and turnaround time, so that your facility can be up and running when you need it to be.

Arc Flash Studies for Existing Facilities – Change is Constant

Electrical systems are constantly changing:

- It could be that new equipment has been added to your facility

- Or the utility company has changed transformers related to your facility

- Or the closest substation has made changes

Any of these changes have a direct impact on arc flash hazards on your site which means that you need an arc flash study to address the modifications.

Even in the unusual case that nothing has changed over the years, the NFPA-70E Standard requires that an arc flash study be updated every five years at minimum. If your facility hasn’t had a study within that time frame, it means you’re due for a study. Our goal is to get that study done as quickly and cost effectively as possible. We know time is short, and we pride ourselves on our ability to deliver these complex studies quickly.

In an existing facility, the arc flash study consists of several phases including data collection, a short circuit study, a coordination study and then finally the arc flash assessment itself.

Phase 1: Data Collection

Accurate data collection is critical for a precise arc flash study. By gathering all the relevant information our engineers can reduce assumptions about onsite conditions. By focusing on bringing together relevant data, the engineer can deliver accurate study calculations and appropriate site recommendations. The reason this matters to you is that you receive the PPE recommendations that keep your employees safe.

A short-circuit study is an analysis of an electrical system that determines the magnitude of the currents that flow during an electrical fault. Comparing these calculated values to the equipment ratings is another way to ensure that your equipment does not have disastrous failure.

A coordination study ensures that your electrical equipment is coordinating properly so that in the event of an incident, downstream breakers trip first thereby minimizing power outages, and ensuring electrical equipment is properly protected.

- NFPA-70E Standard aligned study in accordance with IEEE Standard 1584

- Accurate arc flash labels/stickers which detail critical arc flash & shock hazard information

- PPE recommendations to ensure personnel safety and comfort

- Protective device coordination to minimize power outages & equipment failures

- Potential hazards identification to improve system safety & protection

- Study calculations include: arc flash incident energy, arc flash boundary distances, trip times, arcing fault values & fault current analysis

What are short circuit and coordination studies?

You are probably wondering why we are talking about short circuit and coordination studies if all you want is an arc flash study and the arc flash labels. In an existing facility, an arc flash study includes both a short circuit study and a coordination study. Think of them as phases of the arc flash study itself.

A short circuit study enables us to create a model of the electrical distribution system in question. That model highlights sources of fault current and system impedances within a power system. This information is then used to ensure that electrical equipment is properly rated for the fault current it could experience if a short circuit were to occur. In essence, the model is developed to prevent potential short circuit safety issues or catastrophic equipment failure.

As far as the coordination study goes, it’s all in the name – a coordination study ensures that your electrical equipment is doing just that – coordinating properly. The goal of the study is to ensure that all electrical systems function as intended and that protective devices trip in sequence as intended during an electrical fault or overload. The end goal is to protect both personnel and equipment on site and to mitigate costly system breakdowns. Coordination studies are part of the mandatory compliance requirements as required by the NEC.

Why do I need an arc flash study?

You need an arc flash study to comply with regulations and to keep your employees and facility safe. Arc flash studies determine the minimum level of Personal Protective Equipment (PPE) workers must wear when they are near exposed energized equipment.

Simply put you need the study – so that this doesn’t happen… The study is done to ensure personnel & equipment safety and to comply with OSHA mandates.

At PPG we take a complex process & simplify it for our customers. The result is an industry standard, accurate & cost-effective solution – delivered quickly – for your timeline & budget. Request a Quote for your Arc Flash Study.