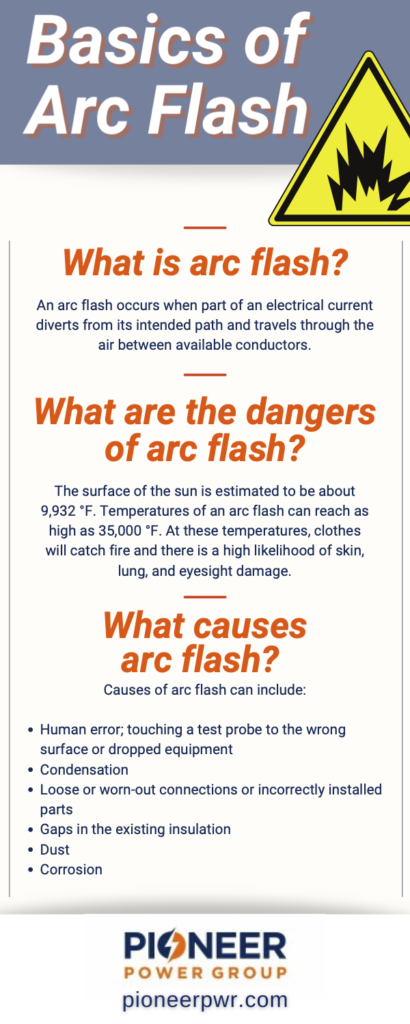

What Is an Arc Flash?

Let’s start at the basics of arc flash. What is an arc flash? An arc flash occurs when part of an electrical current diverts from its intended path and travels through the air between available conductors. Arc flash is a tremendous safety hazard for humans, as being electrocuted in this manner often results in serious injuries, and in extreme cases, death. According to the Bureau of Labor Statistics, between 5 and 10 arc fault incidents occur in the United States every day. For this reason, there are strict regulations regarding the safety measures that must be taken to prevent arc flash hazards.

What Are the Dangers of an Arc Flash?

The surface of the sun is estimated to be about 9,932 °F. Temperatures of an arc flash can reach as high as 35,000 °F. In the presence of these extreme temperatures, clothing and skin can catch on fire almost instantly. There’s also the risk of melted metal, lung, and eyesight damage.

What Causes an Arc Flash?

Arc flash is caused by several different factors, but chief among them is a spike of electricity, called a voltage transient, switching from reactive loads or lightning strikes. The flash can be incredibly brief — shorter than a few microseconds.

Other causes of an arc flash can include:

- Human error: touching a test probe to the wrong surface or dropped equipment

- Condensation

- Loose or worn-out connections or incorrectly installed parts

- Gaps in the existing insulation

- Dust

- Corrosion

How Are Arc Flash Injuries and Fatalities Prevented?

Due to the severity of arc flash injuries, OSHA stipulates strict precautions for preventing arc flash. Three main factors determine the severity of arc flash injuries:

- How close is the worker to the hazard?

- What was the temperature of the arc flash?

- How long did it take for the circuit to break?

With these questions in mind, workers are trained to understand specific approach boundaries around equipment that may carry the risk of arc flash incidents. The National Fire Protection Association breaks down the boundaries around equipment into four zones, including:

- Flash Protection Boundary (the outermost boundary)

- Limited Approach

- Restricted Approach

- Prohibited Approach (the innermost boundary)

In addition to maintaining strict boundaries around hazardous equipment, electrical workers will also carry personal protective equipment, an Energized Work Permit, and insulated tools. Each worker will also receive a thorough job briefing and details of the written safety programs on site.

Contact Us for Your Arc Flash Analysis

For more information about how arc flash studies save lives, OSHA electrical regulations, and our suite of services, don’t hesitate to reach out to our team today!