An arc flash study is required to comply with government mandates and regulations.

These power studies are also required to prevent death and injury in the workplace. Sadly, some of our current clients have come to us after an arc flash related death of an employee at one of their facilities. The most common cause of an arc flash incident is human error. Arc flashes can occur when maintenance workers are manipulating live equipment for testing or repair, and accidentally cause a fault.

Some of the causes of arc flash events are:

- Improper tools & electrical equipment

- Corrosion of equipment

- Incorrect work techniques

- Lack of training

The best way to prevent an arc flash from occurring is to conduct an arc flash analysis.

Simply put, if you want to run your facility safely, you’ll need a study.

From concept through to delivery, our engineers will make sure that your facility meets government regulations and that your employees are safe.

Arc flash studies save lives and keep your facility running smoothly.

What is an Arc Flash

An arc flash is an explosion that is triggered by an electrical arc; basically, it is an electrical short circuit through the air. It can occur from phase to ground or phase to phase. With temperatures that can exceed 35,000°F (that’s about 4x the temperature of the surface of the sun) in 1/1000 of a second, arc flash events can be extremely intense. Thermal energy can be dissipated as radiant, convective, and conductive heat, resulting in extreme risks to both personnel and equipment.

What causes an Arc Flash?

An arc flash occurs when part of an electrical current diverts from its intended path and travels through the air from one conductor to another, or to the ground. An arc flash can vaporize electrical equipment, cause fatal burns, generate a blast wave that can collapse workers lungs and rupture eardrums, and in some cases even cause death.

Unfortunately, arc flash incidents are tragically common in the United States with 30,000 annual events resulting in 2,000 hospitalizations and 400 fatalities per year. An arc flash can occur in an instant, escalating in less than a 1/1000 of a second.

An arc flash event can be caused by many different factors including:

- Human error:

- Improper equipment installation / labelling

- Faulty equipment operation

- Working on live equipment / failure to confirm absence of voltage

- Failure to use appropriately insulated tools

- Accidental falls / sudden movements / dropped equipment

- Incorrect use of test probes

- Equipment failure

- Poorly maintained switchgear/circuit breakers

- Loose or worn-out connections

- Insulation gaps

- Environmental contamination

- Faulty test equipment

- Environmental factors

- Dust

- Corrosion

- Condensation

- Contamination (process material, insects, vermin…)

- A voltage transient (a spike of electricity) caused by circuit switching

- Lightning strikes

- Static electricity

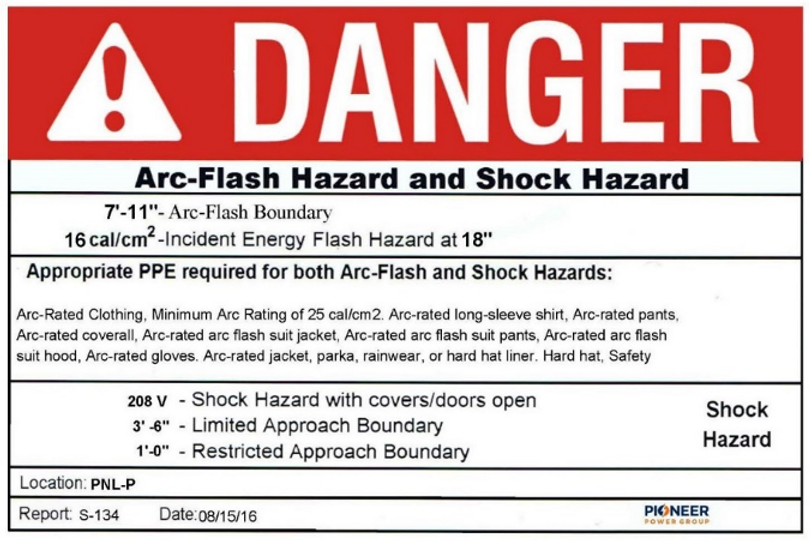

What is an Arc Flash Label?

Arc flash studies are complex studies that result in two simple deliverables – an arc flash label and a comprehensive report. Arc flash labels (also sometimes referred to as arc flash stickers) are designed to warn workers of hazards and to provide recommendations on required Personal Protective Equipment (PPE) when in the area. Each area of concern in a facility will receive a label.

NFPA-70E was developed at OSHA’s request and sets the standards for electrical safety in the workplace. The goal of this regulation is to protect personnel by reducing exposure to major electrical hazards. The regulation helps companies and employees avoid workplace injuries and fatalities.

In short, NFPA-70E requires an arc flash study to identify arc flash hazards, associated arc flash boundaries and required PPE.

ANSI approved arc flash hazard warning labels are created to clearly identify the hazards of a given electrical panel and provide recommendations on the appropriate PPE. The labels warn workers of potential arc flash hazards, voltage, arc flash boundary and required PPE for safety.

The information on an arc flash label is based directly on the results of the arc flash study.

Is an Arc Flash Study Required by OSHA?

- OSHA (Occupational Health & Safety Administration) mandates that an electrical risk assessment be conducted for any new build or existing facility. This assessment is conducted to provide employees with the proper protection (PPE) for any hazards that are identified at the site. Arc flash studies do not eliminate risks, but rather identify them and provide appropriate safety protocols to meet government standards and to ensure personnel and equipment safety.

- Specifically, the OSHA General Duty Clause (5)(a)(1) requires that each employer furnish employees with “employment and a place of employment which are free from recognized hazards that are causing or likely to cause death or serious physical harm to the employees.” More specifically OSHA 29CFR 1910.335 (a) (1)(a) requires the use of protective equipment when working where a potential electrical hazard exists and 29CFR 1910.132(d)(1) requires the employer assess the workplace for hazards and the need for personal protective equipment.

- Once an arc flash hazard analysis has been completed, you will be able to have your employees properly trained on arc flash safety, as stated by OSHA 29FCFR1910.332. Failure to comply can result in fines and penalties leveled at your company by OSHA.

- NFPA 70E Standard for Electrical Safety in the Workplace, Article 130.5 states that a study needs to be done when there is a significant change in the electrical system or “reviewed for accuracy at intervals not to exceed 5 years”.

- NFPA 70E Standard for Electrical Safety in the Workplace, states that a “Flash hazard Analysis shall be done before a person approaches any exposed electrical conductor or circuit part that has not been placed in an electrical safe work condition”.

- IEEE 1584 and NEC provide further guidance on the arc flash regulations required by OSHA, with specific details pertaining to performing arc flash hazard studies, analyses and calculations. NEC requires labeling of equipment to warn of potential arc flash hazards. Each panel must be marked with ANSI approval Arc Flash Warning Label.

Pioneer Power Group Can Help

Facility owners can rely on PPG to provide reliable arc flash study services. With our strong technical background and industry expertise, our engineers always try to go above and beyond to serve our clients. For more information about arc flash analysis or any of our other power studies, contact us today.